Solutions for all plant conditions

Designed for a precision landing

Each plant has its individual profile, even within one particular industry sector and technical progress always brings new challenges. The RITAG product range is "alive". The products from A to Z have all been designed to meet any plant conditions and sizes with flexibility and with the customer in mind. Today, tomorrow and the days after tomorrow. Numerous innovations and patent applications underline our capability to meet and grow with our customers' demands.

Tailor-made solutions are designed in collaboration with plant designers and operators which, depending on their particular needs, usually far exceed the mandated standards. Of course we utilise the best available tools and systems to achieve this spot-on "landing". We provide a sufficiently large production area and two 10-ton cranes, 9 m high and with a 25 m span, to maximise the space for your requirements.

- Standard-compliant products, certified for all international markets

- Wafer Type Check Valves/DISCO Check Valves/High Pressure Valves

- Swing Check Valves

- Dual Plate Check Valves

- Nozzle Check Valves

- Tank Bottom Valves/Bottom Outlet Valves

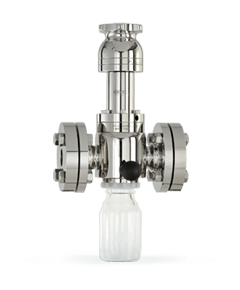

- Sampling Valves/Sampling Systems

- Clean Service/ Cleanable valves

- They have been designed for use in industrial installations handling oil and gas, chemicals, the petrochemical industry and pharmaceuticals, energy industry and shipbuilding.

- Modern production with a very broad production range

- Special materials for each challenge

- Extremely high diversity in variants

- Anything is possible, from the standard solution to the most special request