Proven, a thousand times over

RITAG industrial valves for any application

Whether as a standard product or as a custom order: RITAG wafer type check valves are available in any nominal diameter, pressure level and material for your processes.

The development and manufacture of our high-quality valves are in compliance with all international standards and regulations.

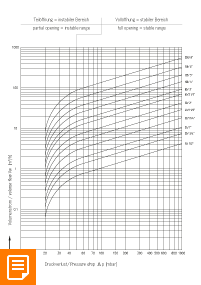

RITAG Type SR wafer type lift check valves

These models have been installed in plants around the world for decades. Some of the most common areas of application are hot water plants, plants for water and waste water treatment, boilers and supply systems, energy pipe systems and process equipment for the chemical and petrochemical industries. Our standard product range already takes care of the most important application ranges. RITAG extends this application spectrum far beyond standard uses by offering special variants with specific materials, nominal diameters, nominal pressure ranges and opening pressures.

- Use as nonreturn valves and thermosiphon circulation cross-dam

- Installation in any location

- Great connection variety, such as wafer type, double flanged, weld end

- For fluids, gases and vapours

- Large selection of materials for any requirement

- Seals made of a variety of materials with the appropriate resistance to the materials running through them

- Tests, certificates and approvals

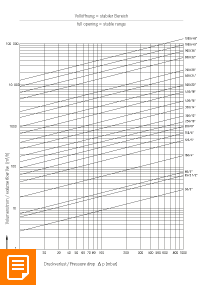

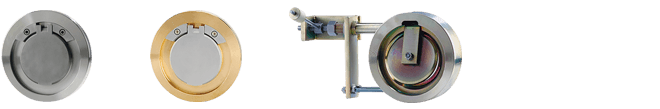

RITAG Type ZRK and ZRL-HG wafer type swing check valves

RITAG Type ZRK is used most commonly in pipe systems for industrial applications of all kinds. These wafer type swing check valves are virtually maintenance free. The seat seal can be an elastic or a metal to metal seal. The flap disc is self-centring and secured – using a special stop for protection against pipe damage.

The RITAG Type ZRL-HG wafer type swing check valves with external shaft are also used in piping systems across all industrial applications. The model is designed for gaseous and liquid media, under consideration of the maximum differential pressure values. This type is not necessarily the best model for process plant systems.

- Gaseous and liquid media

- Many materials available for any request

- Seals made of a variety of materials with the appropriate resistance to the materials running through them

- Tests, certificates and approvals

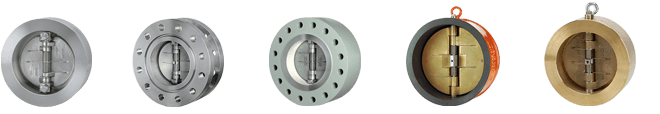

RITAG Type ZRD / DIN and API dual plate check valves

The RITAG Type ZRD dual plate check valve is the most universal check valve among the nonreturn valves. It is available in a broad spectrum of nominal diameters and nominal pressures. Thanks to the dual-plates, which create the optimum dynamic flow behaviour, this valve design has proven to be an outstanding solution for most process requirements in plants and pipe systems. The dual plate check valve is perfectly suited for use with vapours, gases and liquids.The well thought through design requires no drilling in the housing (retainer-less design) and therefore has no housing seal other than the flange seal. Thus, testing for volatile emissions (fugitive emissions) is not required.

- Suitable for all common flange standards and flange facings

- Four different designs for each flange standard are available:

- Wafer

- Flanged

- Solid Lug

- Tapped Lug

- Many materials available for any request

- A large variety of elastomers and metal based solutions are used in the design of these functional seals thus offering a solution for nearly all media.

- Tests, certificates and approvals